Heat Treating

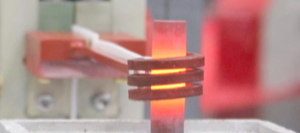

Lepel Heating Process

To compete in today’s market, businesses need to manufacture products less expensively, with less waste, while ensuring the highest quality. Regardless of your process, production efficiency and cost-effectiveness are critical for your operation. However, most radiant and convection heating solutions are inefficient and generate high waste and reject rates.

Lepel’s leading-edge high frequency induction heating solutions are the answer. The induction heating process delivers localized, non-contact heat—resulting in fewer rejects, less scrap, reduced energy costs, and less product distortion. Lepel is recognized for its industry-leading expertise in high-frequency induction heating. Our decades of experience and innovation in the field enable us to address your most demanding heating challenges. We’re continually developing induction heating solutions for new and interesting applications.

Lepel’s Induction Heating Process Offers:

- Improved product quality. The contact-free process induces heat in the product without touching it, reducing the opportunity for damage. Reduced energy costs. Unlike inefficient furnaces, the induction heating process converts up to 80% of the expended energy into useful heat, offering substantial cost savings.

- Reduced maintenance requirements and costs. Adding solid-state induction equipment to your process can eliminate the excessive maintenance costs associated with large ovens and furnaces. Precision heating with minimized distortion. The precise induction process delivers heat exactly where it is needed, so the other areas of your part are not exposed to possible distortion.

- Reduced excess heating of the manufacturing environment. Induction heating is localized, providing increased employee comfort.

- Reduced emissions of toxins and noise levels. High-frequency induction heating is a clean process, producing no smoke, pollution, waste heat, or noise.

- Drastically reduced cycle times. Instantaneous heat allows for quicker startup and increased production capabilities.

- Higher repeatability. Accurate temperature control provides uniform, consistent results, with fewer rejected parts.

Contact Lepel today to learn more about our heat treating solutions.